Product description

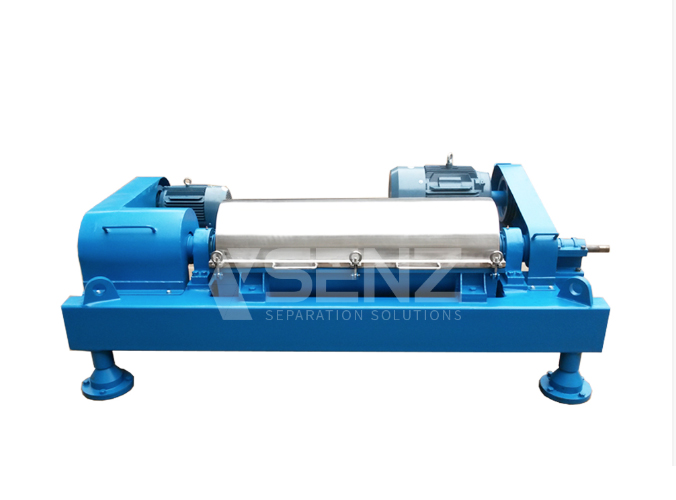

Oil field horizontal screw centrifuge (double motor double frequency conversion type)

The horizontal screw discharge sedimentation centrifuge for oil and gas drilling fluid purification (hereinafter referred to as horizontal screw centrifuge) is designed with an integrated frame body, which is convenient for on-site installation and lifting; The horizontal spiral discharge sedimentation centrifuge adopts special explosion-proof, anti-corrosion, weather resistance and vibration reduction treatment. The frequency converter and other electrical components are installed in the explosion-proof cabinet. The explosion-proof cabinet is equipped with heating and ventilation system, which is suitable for field operation. The screw pusher is driven by planetary gear reducer, with mechanical and electrical double overload protection device, which can realize low-speed and high torque power transmission and stable start.

The horizontal spiral discharge sedimentation centrifuge has the forms of single motor drive, frequency conversion double motor drive, hydraulic drive and so on, which can be selected by users according to different use conditions.

The hydraulic driven horizontal screw centrifuge can not only conveniently change the speed of the drum and the ejector, but also feel the change of the load of the drum and the ejector by collecting the hydraulic pressure, and automatically realize the intelligent functions such as "discharging blockage", "stopping feeding", "alarm", "shutdown" and so on. The hydraulic system adopts integrated technology with high reliability and convenient maintenance.

Drilling centrifuge is a five stage solid particle control equipment in the drilling mud solid control system. It uses the principle of centrifugal sedimentation separation to separate the suspension in the drilling fluid. It balances the viscosity and specific gravity of the drilling fluid in the drilling field, recovers the heavy diamond powder in the drilling fluid and saves the drilling cost; It mainly separates 2 ~ 5% of drilling fluid μ m,5~7 μ M solid particle is an essential and important equipment in the field of oil drilling, coalbed methane drilling and environmental protection waste mud treatment. Combined with centrifugal separation technology and on-site working conditions in the field of foreign drilling and combined with domestic petroleum universities and enterprises, this product can be used for solid-phase control in the fields of oil drilling, trenchless, coalbed methane and so on. At the same time, it can be used for tail rotor treatment of drilling fluid, solid-liquid separation in environmental protection industry, as well as food Medicine and other fields. At present, the drilling centrifuges developed, designed and produced by Zhengdao company mainly include low-speed centrifuges, medium speed centrifuges, high-speed centrifuges and high-speed frequency conversion centrifuges.

Equipment characteristics

1. Good operation stability: This machine adopts involute planetary gear differential and has our unique low oil level operation technology. The working temperature is low, the transmission torque is large, and the performance is reliable. The drum main bearing adopts thin oil forced circulation lubrication, which can effectively improve the running speed and adapt to high temperature conditions.

2. Circulating lubrication system: pressure oil circulating lubrication provides a good lubrication method for the main bearing and reduces the operating temperature of the bearing, which can greatly prolong the service life of the machine.

3. Safety protection device: This machine has multiple protections such as high torque protection feedback, revolution control, oil temperature display, main bearing temperature display and alarm, which can effectively eliminate or reduce the damage to millions of machines caused by sudden faults.

4. High degree of automation: the feeding, separation, unloading and other operations of the machine operate continuously and automatically at full speed. The functional design of the sedimentation section is strengthened, which has obvious adsorption effect on the fine particles in the suspension, improves the recovery capacity of the small particles, and can process 15-30 tons of suspension per hour.

5. Good operating environment: the separation of meat stopping day is carried out under completely closed conditions. There is no pollution to the operation site, and the production environment can be kept clean and tidy.

6. Strong corrosion resistance: the drum, screw, casing and other parts of the machine invaded by rabbit meat are made of high-quality stainless steel, which has sufficient acid and alkali resistance. At the same time, other materials can also be selected according to the needs of users.

7. Good wear resistance: the spiral blade of this machine adopts the process of surfacing cemented carbide to enhance the wear resistance. It is suitable for solid-liquid separation of non-metallic materials.

8. Good operation stability: This machine adopts involute planetary gear differential and has our unique low oil level operation technology. The working temperature is low, the transmission torque is large, and the performance is reliable. The drum main bearing adopts thin oil forced circulation lubrication, which can effectively improve the running speed and adapt to high temperature conditions.

Material selection

According to the user's requirements, the product contact can be made of austenitic stainless steel (321, 316L...), Haines alloy, titanium alloy or other anti-corrosion materials.

Structure and working principle

Horizontal screw centrifuge realizes solid-liquid separation by accelerating the settling speed of solid particles under the action of centrifugal force due to the density difference between solid and liquid phases.

The centrifuge is composed of two rotors, one is called drum, and the other rotor is spiral discharger (spiral for short). When the drum rotates at a high speed, the slurry in the drum rotates with the drum and is subjected to centrifugal force, which is many times greater than gravity. In this way, the solid particles will be separated from the liquid and settle on the inner wall of the drum from the axis of the centrifuge drum. The screw unloader in the drum rotates at a speed lower than that of the drum and pushes the deposited solid particles to the slag outlet, The differential speed between the outer drum and the screw unloader depends on the transmission ratio and speed of the differential.

Technical parameter

Users can reasonably select the working parameters of the centrifuge according to the physical properties of the separated material (suspension), separation requirements, treatment capacity, process requirements and other factors, so as to obtain satisfactory separation effect and economic benefits. Colors and materials can be customized.